In modern commercial popcorn production, selecting an efficient, energy-saving, and easy-to-operate popcorn machine is essential. As a professional food processing machinery manufacturer with 12 national patents, Shandong Longze Machinery Co., Ltd. offers a variety of commercial popcorn machines. Among them, the gas-powered popcorn machine and the induction popcorn machine are currently the two most widely used heating types.

So, what are the differences between these two types in terms of heating efficiency, energy cost, operational safety, and applicable scenarios? Which one better suits your business needs? This article provides a detailed comparison of our gas-powered and induction popcorn machines across multiple dimensions to help you make a more informed decision.

Comparison Overview

| Feature | Gas-Powered Popcorn Machine | Induction Popcorn Machine |

|---|---|---|

| Heating Method | Operates on liquefied petroleum gas (LPG) or natural gas | Utilizes electromagnetic induction heating technology |

| Capacity(Customizable) | 100L | 100L |

| Output/Hour | 55kg | 75kg |

| Ease of Operation | Requires connection to gas pipelines or gas tank replacement; traditional ignition process | Plug-and-play design, adjustable temperature, supports smart temperature control |

| Safety | Requires proper ventilation and fire prevention measures | Flameless design, safer for indoor environments |

| Cleaning & Maintenance | easy | easy |

| Ideal Application Scenarios | Suitable for outdoor events, exhibitions, theaters, or factories with gas access | More suitable for indoor environments such as restaurants, cinemas, and chain stores with stable power supply |

| Customization Options | Supports customization of capacity, stirring system, outlet height, etc. | Supports customization of power settings, automation level, intelligent interface functions |

Best For | Startups, low-energy-cost regions | High-volume retail, mid-size factories |

| Ongoing Operating Cost | Gas source cost + regular maintenance fees | Electricity cost + almost no fuel maintenance required |

*All models feature direct oil-popping technology and SUS 304 stainless steel construction.*

Core Equipment: Your Production Powerhouse

* At the heart of your operation is the industrial popcorn machine. Cutting corners here risks bottlenecks, inconsistent quality, and hidden costs. Today’s leaders prioritize:

Oil-popping technology: Eliminates need for separate coating machines by infusing flavors directly during cooking (e.g., spicy, cheese, or caramel).

Heating flexibility: Choose between gas (lower upfront cost) or electromagnetic (precision temperature control + higher yields + more efficient).

Stainless steel construction: Mandatory for food safety, durability, and compliance with global standards (ISO9001, CE) 24.

Strategic Considerations Beyond Machinery

Power Requirements: Electromagnetic models (LZ-DCB-100L/200L) need 3-phase power but reduce thermal loss vs. gas.

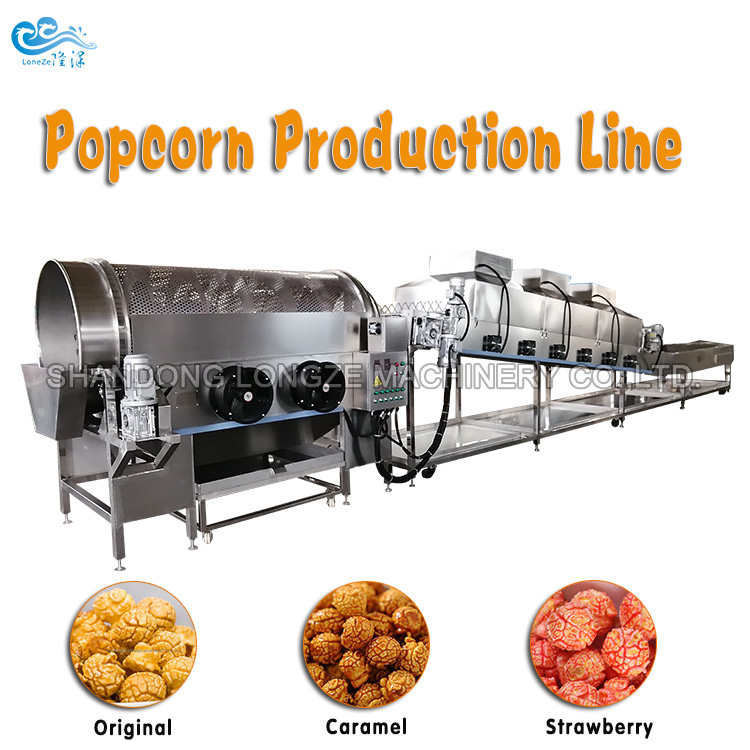

Space Planning: The area occupied by a popcorn machine is about 3.5㎡-6㎡. The production line covers an area of about 12.5㎡-26㎡.

Compliance: CE certification is non-negotiable for export markets 27.

Whether you choose a gas-powered popcorn machine or an induction popcorn machine, Shandong Longze Machinery is committed to providing you with high-performance, reliable, and safe commercial popcorn solutions tailored to your specific needs.

Gas models are favored by many small and medium-sized businesses due to their mature technology and lower initial investment. Meanwhile, induction models offer advantages such as energy efficiency, environmental friendliness, intelligent operation, and enhanced safety, making them ideal for high-end markets and indoor environments.

Ultimately, the choice depends on your actual application scenario, budget, and operational requirements. If you need further information about our product specifications, customization options, or sample test videos, please feel free to contact our sales team. We will provide you with professional advice and one-stop service.