Shandong Longze Machinery Co., Ltd. is dedicated to providing innovative and reliable automated solutions for global food processing enterprises. Our newly developed Large-Scale Intelligent Mushroom Popcorn Production Line has been meticulously upgraded by the Longze R&D team based on traditional popcorn machines, incorporating customer feedback and market demands. It has now become a trusted industrial-grade popcorn solution for international clients.

Core Technological Advancements

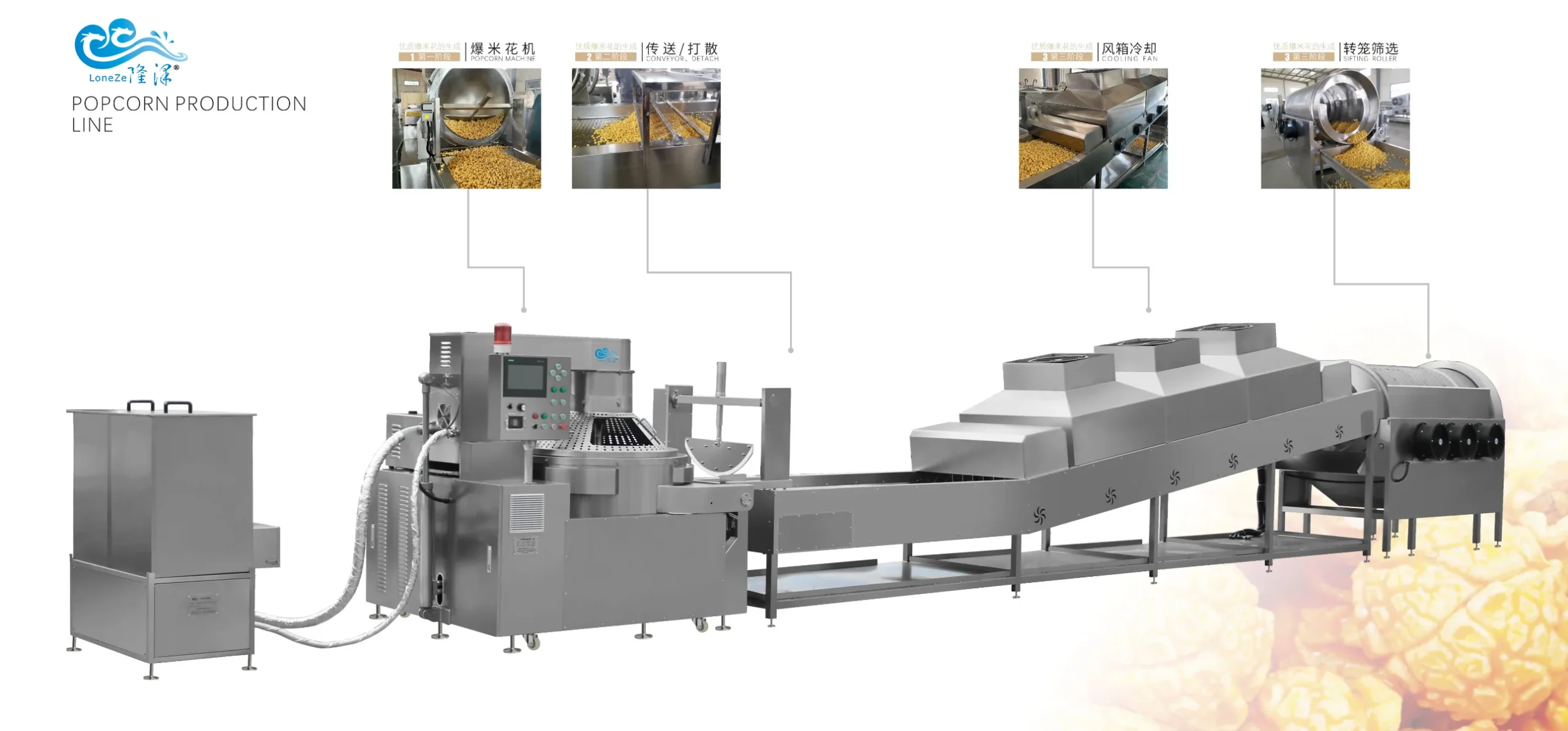

1.Optimized Mixing & Sugar Coating System

Features a newly designed agitator and syrup spraying system to ensure even heating and complete sugar coating, preventing clumping and enhancing taste and appearance consistency.

2.Enhanced Furnace Environment

Improved furnace structure and heat transfer design enable rapid heating, significantly reducing preheating time, boosting productivity, and saving energy.

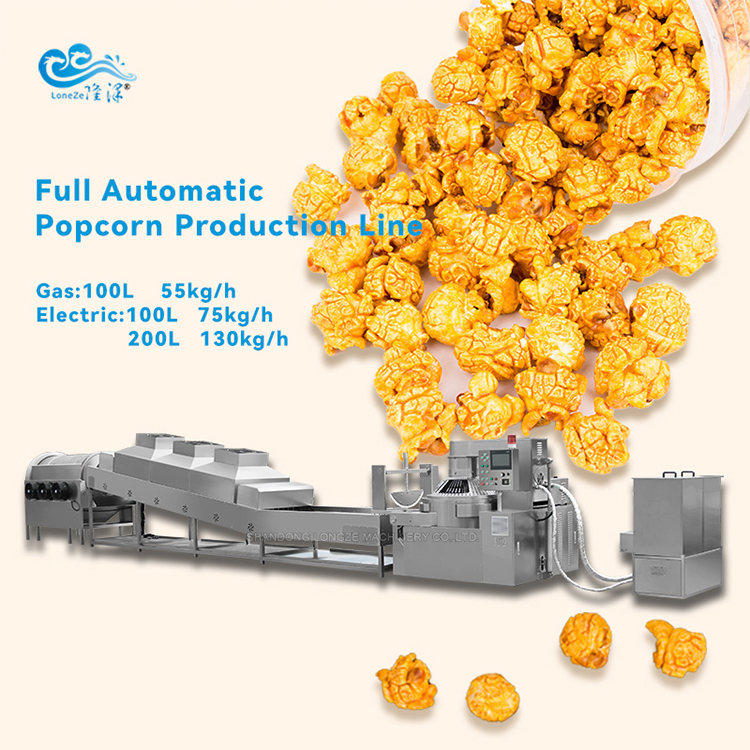

3.Dual Heating Options Available

Meets diverse regional energy and environmental requirements. Customers can choose based on their needs:

- Ideal for areas with stable gas supply – low cost, fast heating.

- Clean and eco-friendly, with precise temperature control and smart operation, meeting modern factory standards.

TECHNICAL DATA

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Capacity | Overall Dimensions |

| LPG | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | =50kg/h | 1207x1500x1500 |

| ElectricInduction | Electric Induction 20Kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligent | =75kg/h | 1565x1373x1606 |

| Intelligence | Electric Induction 40Kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligent/Automatic Feeding | =110kg/h | 1541x1851x1675 |

All models feature automatic hydraulic discharge for safe, easy operation and reduced labor intensity.

Why Choose Longze Industrial Popcorn Machines?

Premium mushroom-style popcorn – full, round kernels ideal for premium snacks, cinemas, and tourist spots.

High output & continuous operation – integrates with auto-feeding, cooling, and packaging for full automation.

Food-grade 304 stainless steel contact parts, compliant with FDA, EU standards.

Optional intelligent control for precise temperature management and process logging.

Global support: Installation, commissioning, operator training, and long-term technical service.

Target Markets & Customers

- Snack Food Manufacturers

- Cinemas & Amusement Parks

- Tourist Attractions & Commercial Streets

- Wholesale & Retail Brands

- Export Trading Companies